Construction Industry Cylinder Honing Machine

TECHNICAL SPECIFICATIONS Gun drilling and BTA Combined drilling machine (Model: ZK2108Fx2×2500mm ) Machine Operation: BT

Description

Basic Info.

| Model NO. | honing-02 |

| Hole Diameter | 50-100mm |

| Automatic Grade | Semiautomatic |

| Precision | Precision |

| Certification | ISO 9001 |

| Condition | New |

| Main Motor | 55kw |

| Feeding Motor | 7.5kw |

| Center Height | 800mm |

| Drilling Depth | as Require |

| Transport Package | Sea Transport |

| Specification | 10 ton |

| Trademark | Ruicheng |

| Origin | China |

| HS Code | 8501109101 |

| Production Capacity | 200 Sets Per Year |

Product Description

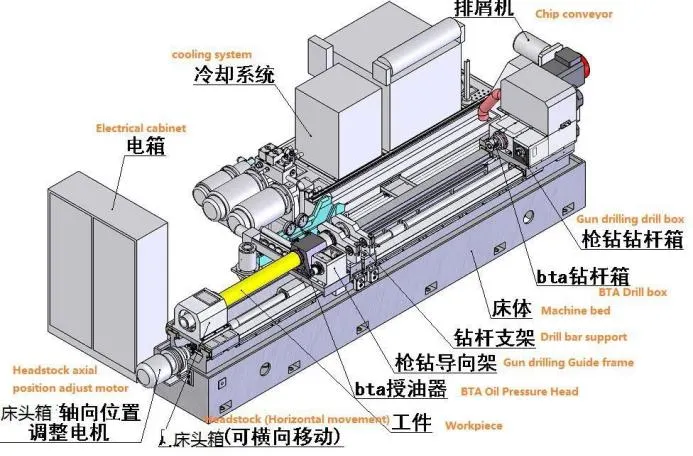

TECHNICAL SPECIFICATIONSGun drilling and BTA Combined drilling machine (Model: ZK2108Fx2×2500mm )

Machine Operation: BTA Method (Internal chip removal ) , Gun drilling method (External chip removal). These two processing method cannot be used at the same time.

Machine Specifications:

| Technical Items | Parameters |

| Gun drilling diameter range | Φ4mm~φ30mm |

| BTA drilling diameter range | φ25mm~φ80mm |

| Max.Hole drilling depth | 2500mm |

| Max.workpiece Length | 2500mm |

| Workpiece OD range | Φ50~Φ200mm |

| CNC control system: | GSK system |

Machine brief:

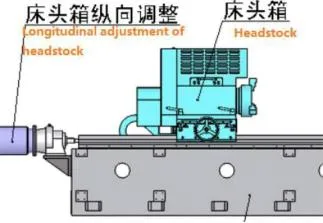

- The machine adopts horizontal layout, using gun drill (External chip removal) and BTA (Internal chip removal) two processing methods, the two processing methods can not be used at the same time. For example, when using gun drill, BTA can not be used; workpiece is clamped on the machine by chuck and cone disc;cutter tool and workpiece rotate relatively, and cutter tool feed.

When the gun drill and BTA are converted, it is necessary to change the cutter, auxiliary tools and oil circuit manually, so that the conversion of the two processing modes can be realized.

The machine adopts double spindle structure. The gun drilling drill box and BTA drill box are assembled on one bracket and share one infeed system.

- Machine features:

- It has two processing methods: gun drill (external chip removal) and BTA (internal chipremoval). Double spindle structure, one spindle for gun drilling, the other spindle for BTAprocessing.

- Bed body, box body, worktable and other basic parts are cast with high quality cast iron.

- Equipped with special cooling system: composed of automatic chip conveyor, oil cooler, filtersystem, high-pressure pump group, etc.

- Z-axis feeding guide is double rectangular sliding guide with good rigidity.

- The spindle motor is used to drive the cutter tool rotation, and the feed of the tool is realized by the ball screw driven by the servo motor. Stepless speed regulation can be realized by rotating and feeding thecutter.

- Electrical system: it was controlled by CNC system, which can not only program and set up the automatic processing cycle, but also can adjust manually, point, start and close.

- The machine has the functions of pressure protection, liquid level and temperature protection of cooling system, tool protection and stroke protection.

Machine mainly Parameters:

Specification Parameters Note

Working capacity

Drilling diameter rangeGun drilling Φ4~Φ30mm BTA Φ25~Φ80mm Max.drilling depth 2500mm Max.workpiece length 2500mm Workpiece OD range Φ50~Φ200mm Machine Drill box for Gun Max.rotary speed 10000r/min Stepless performance drilling Main motor power 7.5KW Spindle motor

Drill box for BTAMax.rotary speed 2000r/min Stepless Main motor power 30KW Spindle motor

Z axisInfeed speed range 5~500mm/min Stepless Rapid traverse rate 2000mm/min Motor torque 23Nm

OthersMax.hole-Length ratio 100:1 Machine total powe(r roughly) 70kW Machine floor space(roughly) 9m(L)×3.4m(W) Machine total weight(roughly) 15T CNC system GSK

Cooling system

Max.PressureGun drilling 10MPa BTA 5 MPa

Max.flowGun drilling 100L/min BTA 300 L/min Filtering accuracy 40μm

Dezhou Ruicheng Machinery Manufacturing Co., Ltd, located in Dezhou City, Shandong Province, the "Hometown of Deep Hole Processing" in China. It is an industrial and trade enterprise integrating of R&D, manufacturing and sales. The factory have very convenient transportation because of 300km to Beijing Daxing International Airport and nearly 250km to Qingdao Port.

The company was founded in 2009, has 10 experienced technicians, 15 sets of high-precision production and testing equipments. That is why we are confident with the delivery time and quality.

The company's superior products: scraping and rolling machine and tools, deep hole drilling machine, deep hole boring machine, deep hole honing machine and deep hole BTA drills, deep hole trepanning machine and tools, deep hole boring heads, deep hole expanding tools, reaming tools, honing More than a dozen product types and hundreds of specifications such as deep hole drill inserts ,guide pads, drill (boring) bars, etc. Widely used in military industry deep hole processing, coal hydraulic cylinder processing, hydraulic parts, aerospace industry, automobile engines , energy and other fields.

We focuses on R&D and innovation, and strictly inspects of product quality to meet the needs of different customers. Famous in Iran, India, Singapore, Pakistan, Indonesia, UAE, Russia,India and other countries.

We take the goal of becoming an excellent deep hole processing manufacturer and service provider and keep on going ahead.

Welcome customers home and abroad to visit our factory.

Prev: T21 Series Deep Hole Drilling and Boring Machine (traditional type)

Next: Screw CNC Milling Table Machine for Extrusion Machines and Granulators

Our Contact

Send now